I feel belay-loop strength is still a relevant subject and wanted to bring it back to everyone's attention, especially since I still get emails from people asking me about belay loop strengths and when they should retire a harness. Below I do my best to answer a few of these questions, while most likely actually posing more questions, as well as provide some super-unofficial non-complete experimental data on belay loops that my QC crew and I performed.

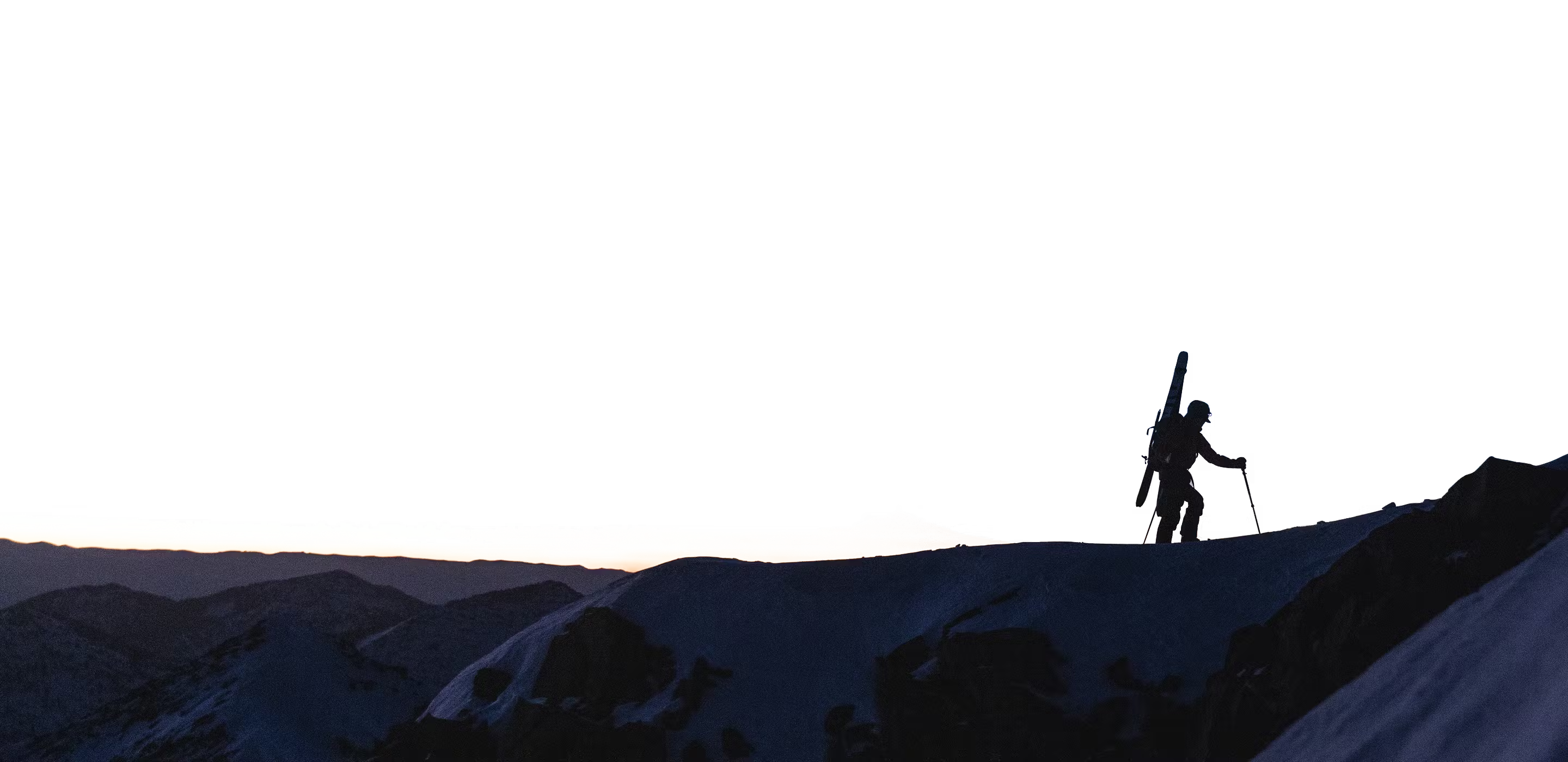

Close-up photo of belay loop

CE requirements: The CE required testing is a bit difficult to describe, but basically, the belay loop must withstand 15 kN for a period of 3 minutes.

Actual Black Diamond test data: Though our inline batch test rating is 3372 lbf, we regularly see belay loops test to over 6000 lbf, with a historical average of over 5000 lbf. * Note: I've tested several other manufacturers' belay loops and they all are in the same ballpark for ultimate strength.

How long should a harness last?

Again, from the Black Diamond Harness Instructions:

Care and Maintenance :

- Machine wash your harness in warm water on a gentle cycle. No bleach. Anytime your harness gets wet, allow it to drip dry away from direct sunlight before storing.

- Harnesses must not come into contact with corrosive materials such as battery acid, solvents, gasoline or chlorine bleach.

- Do not allow your harness to be exposed to temperatures above 140° F (60° C) or below -80° F (-62° C).

- Do not sew, resew, burn or singe loose threads, bleach the webbing, file a buckle, modify, or change a harness in any way.

Storage and Transport:

- Never store a wet or damp harness.

- Store all of your gear in a clean and dry environment, out of direct sunlight and away from heat sources.

- Keep harnesses and other sewn climbing equipment away from gnawing rodents and pets.

- The nylon in your harness will weaken with age if not stored free from mildew, UV light, temperature extremes or other harmful agents. If a harness has been properly stored for ten years or more, retire it.

- With normal use and proper care, the life expectancy of your harness is approximately three years, and can be longer or shorter depending on how frequently you use it and on the conditions of its use.

Factors that reduce the lifespan:

- Falls

- Abrasion, cuts, wear

- Heat

- Sunlight

- Corrosives

Inspect your harness for signs of damage and wear before and after each use. It is vitally important that your harness be in good condition. A damaged harness must be retired immediately.

Retire a harness immediately if:

- There is any kind of rip or hole in the webbing.

- The webbing is burnt, singed, or melted.

- There are any torn threads, or heavy abrasion to the webbing.

- Bar tacks are abraded or showing wear.

- One of the buckles is cracked, corroded, has a burr, or is damaged or deformed in any way.

- The webbing is faded from exposure to ultraviolet light.

- If a harness has been involved in a severe fall, but is not obviously damaged, it still may be ready for retirement. If you have any doubts about the dependability of your harness, retire it and get a new one.

- Anytime you retire a piece of gear, destroy it to prevent future use.

Below are some photos of the different belay loops I tested (before they were pulled to failure) and their tested values.

~50% cut in belay loop

~75% cut through—both sides—2918 lbf:

~90% cut through

2 of 4 tacks cut—3970 lbf:

All tacks heavily abraded across file surface—5280 lbf

All tacks heavily abraded across file surface—5338 lbf:

All tacks heavily abraded across file surface—7429 lbf:

A Final Word

Is this incident going to cause every climber out there to start wanting two belay loops, or tying a backup webbing belay loop in their current harness or throw their harness away altogether and buy a new one immediately? It shouldn't. Reputable manufacturer's make burly harnesses—bottom line—and don't forget that there are some negatives/concerns about using two belay loops at once in some situations (i.e. tri-axial loading carabiners, etc.)—not good.

Harnesses, and belay loops in particular are super strong for sure, but we can't forget that gear does wear out. Every climber is responsible to know the history of his or her gear and act accordingly. When people ask me about worn gear, or gear that's been dropped, or has undergone a strange or peculiar event, I always have to play the conservative card of "when in doubt, retire it"—because the last thing you want to be thinking of in the back of your mind when you're 20 feet above your last piece of sketchy gear is... "geez, I wonder if that's that biner that I dropped that time," or "I sure hope my harness is in good enough shape to withstand this monster whipper I'm about to take." It's not worth having to worry about—I personally have a hard enough time worrying about trying NOT to fall!

Climb safe,

Kolin Powick

===============================================================

Kolin Powick(KP) is a Mechanical Engineer hailing from Calgary, Canada. He has nearly 20 years of experience in the engineering field and has been Black Diamond's Director of Global Quality since 2002. Kolin oversees the testing of all of Black Diamond's gear from the prototype phase through continual final production random sample testing.